ProductPosition:Home > Product

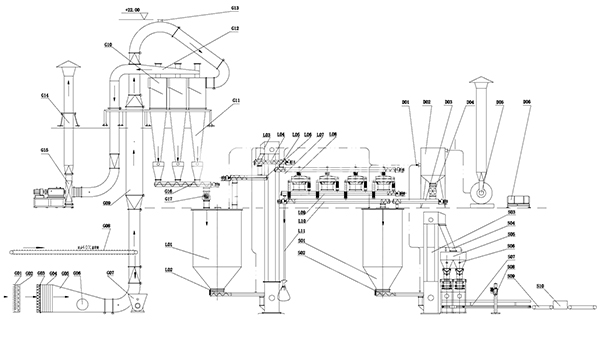

| Diagram of potato starch drying system |

|

Customization Description: the equipment can be customized according to customer requirements.

| G01 |

Louver chimney |

G08 |

Wet starch belt conveyor |

G15 |

Large induced draft fan |

L05 |

Screen upper screw conveyor |

S01 |

Finished product warehouse |

S08 |

Seam bag conveyor |

D04 |

Air shutoff |

| G02 |

Primary filter screen |

G09 |

Pulse tube (expansion tube) |

G16 |

Closed air screw conveyor 1 * 2 |

L06 |

Return screw conveyor |

S02 |

Lever screw conveyor |

S09 |

Intermediate conveyor |

D05 |

Small induced draft fan |

| G03 |

Medium efficiency filter screen |

G10 |

Volute separator |

G17 |

Air shut-off screw conveyor 1 * 2 |

L07 |

Return sliding gate valve |

S03 |

Bucket elevator |

S10 |

Metal detector |

D06 |

Compressed air tank |

| G04 |

Radiator |

G11 |

Cyclone separator 1 * 6 |

G18 |

Starch uniform bin |

L08 |

Circular vibrating screen 1 * 4 |

S04 |

Discharge pipe of bucket elevator |

S11 |

Warehousing conveyor belt |

|

|

| G05 |

Heat exchange box |

G12 |

Wet air outlet pipe |

G19 |

Lever screw conveyor |

L09 |

Under screen screw conveyor |

S05 |

Double weighing and packaging machine 1 * 2 |

D01 |

Dust inlet pipe |

|

|

| G06 |

Inspection hole |

G13 |

Explosion proof port 1 * 6 |

G20 |

Bucket elevator |

L10 |

Sieve screw conveyor |

S06 |

Internal magnetic separator 1 * 2 |

D02 |

Pulse dust collector |

|

|

| G07 |

Feeding conveyor and loudspeaker |

G14 |

Wet air discharge pipe |

G21 |

Bridge screw conveyor |

L11 |

? 150 screen upper material blanking pipe |

S07 |

Intermediate belt conveyor |

D03 |

Dust screw conveyor |

|

|

|

Previous:Pneumatic conveying system for coffee factory in Thailand

Next:Diagram ofThailand citric acid system |

VR

VR

蘇公網安備 32020602000237號

蘇公網安備 32020602000237號